Highlights Formnext 2022

Additive manufacturing technologies are getting more and more popular because they can add value to your products and services in several ways:

- Additional functionality, such as cooling channels, can be integrated in the part

- Customized one-off parts

- Improved availability through print on demand

- Reduced weight through structural changes

- Efficient production through near net shape and low energy cost

- More sustainable because of high material efficiency

Deloro is already utilizing additive manufacturing in the daily manufacturing process, but it also plays an important role for our research and development. These are our individual highlights from the Deloro booth at the exhibition:

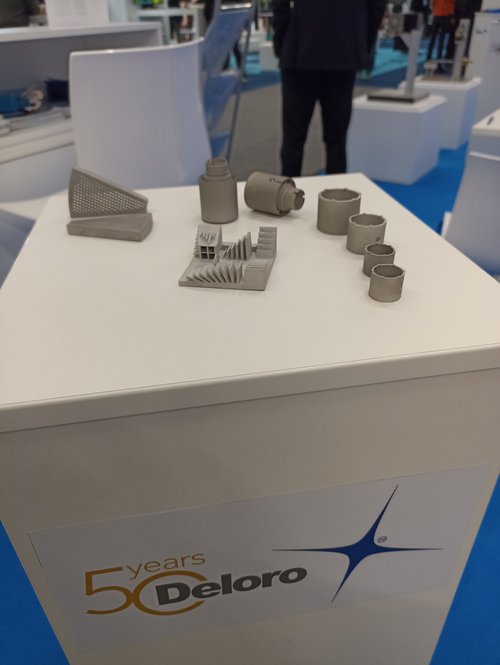

Binder Jetting

Metal Binder Jetting (MBJ) is a sinter-based additive manufacturing process. In collaboration with the Fraunhofer IFAM (Institute for Manufacturing Technology and Advanced Materials) Deloro developed the printing and sintering parameters for cobalt-based StelliteTM alloys. Furthermore, the tensile, wear, and corrosion properties of Deloro additive manufactured alloys were investigated. Tests proved outstanding performance compared to the conventional production of these alloys.

Selective Laser Melting

In the Selective Laser Melting (SLM) manufacturing process, a laser is used to melt the starting material in powder form, layer by layer, and consequently build it up in layers. Together with the Direct Manufacturing Research Center of the Paderporn University we have characterized this new manufacturing process and carried out experimental investigations for Deloro alloys using an innovative heating device that perfectly matches our alloys. We are now capable to print pre-series and small batches in our alloys!

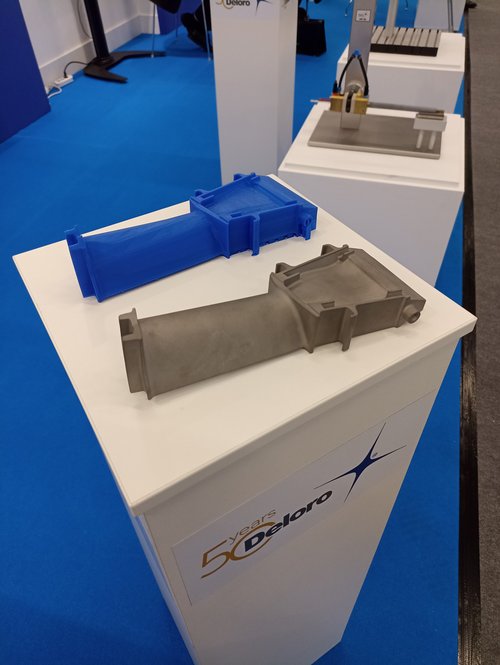

3D Waxprinter for Investment Casting

A wax printer has been an integral part of our investment casting foundry for many years. This technology allows us to cast fresh design ideas without the cost- and time consuming production of a tool and makes small batches of a part possible. The employment of the printer enables modifications to wax assemblies which has resulted in accelerated improvement and development activities. In this way we can eliminate variations due to manual modifications and parts can be made with high amount of detail.

Laser Metal Deposition

In laser powder deposition welding, a laser beam is used to create a molten pool on the surface of a component. A weld bead is created by a relative movement of the processing head and the component. While dense layers are created by the overlapping of weld beads within individual levels, complex, three-dimensional structures can be generated by successive layers. At Deloro a 5kW diode laser in combination with a robot system and turn-tilt table offer the optimal requirements to create new structures or to refurbish worn-out parts.

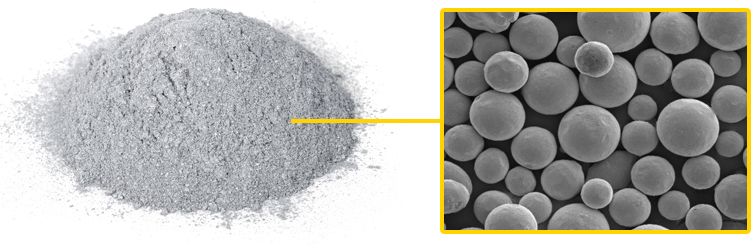

Metal Powder for Additive Manufacturing

We offer a variety of cobalt- and nickel-based powders which are designed for 3D printing available in the grain size distribution of your choice. Our powders are being used in almost every industry sector where an outstanding quality is required. The materials are gas atomized in either Nitrogen or Argon atmosphere with superior results in sphericity, density and flowability.

Gravity Powder Feeder

Deloro gravity powder feeders have been an integral part of Deloro Hettiger PTA welding equipment for long time and are state of the art technology. At the Formnext 2022 a prototype of the stand-alone gravity powder feeder was presented to the community. A stand-alone version of this powder feeder was developed due to the high market demand that surged because of many advantages that come along with this technology: Constant feeding without pulsing even at low feed rates of 2g / minute, aasy powder change and fast discharging, fast switch of powder and less risk of clogging by synchronized movement of powder feeder with torch, fast Coupling System.

Big thank you to everybody who visited us at our booth at Formnext 2022! We are already looking forward to welcome you again next year. In the meantime, or Additive@deloro-team is always available for feedback, discussions and inquiries via E-Mail and contact-form!

Contact us

More on Additive Manufacturing