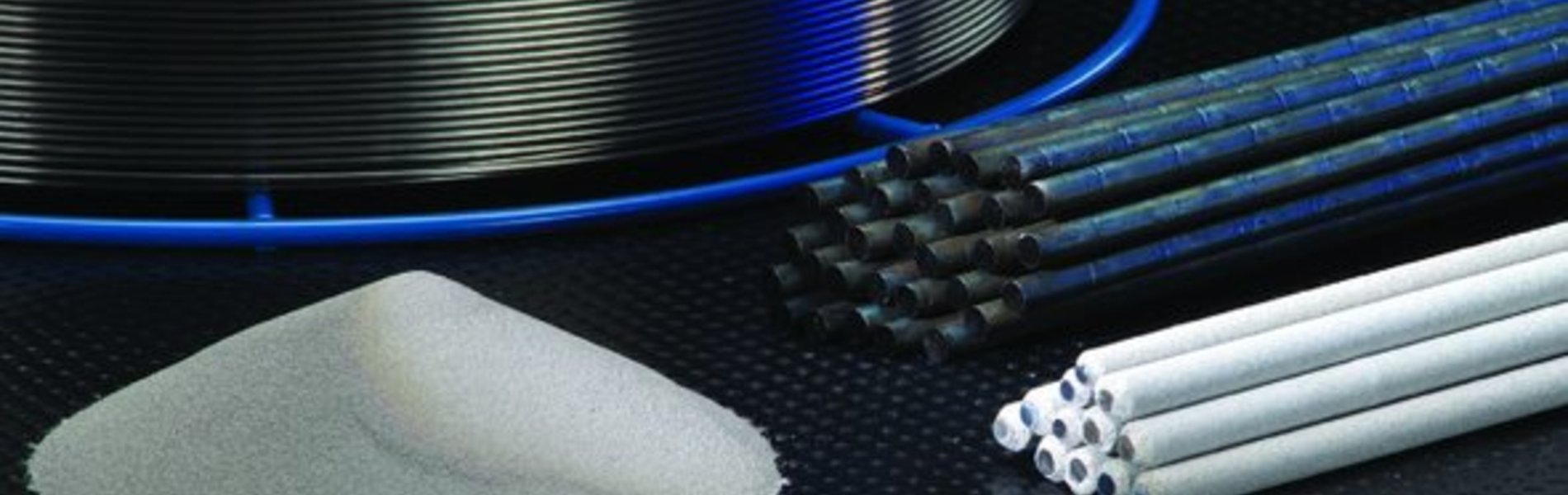

Cladding Consumables and solutions

Powder, wire, rods & electrodes for welding and thermal spraying predominantly Cobalt- and Nickel-based

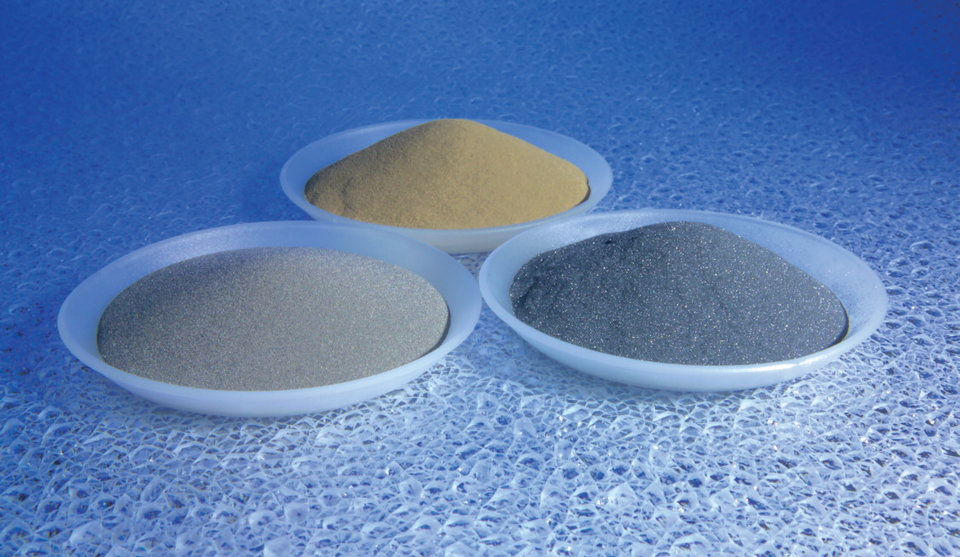

Our powders are being used in almost every industry sector where an outstanding quality is required. The materials are gas atomized in either Nitrogen or Argon atmosphere with superior results in sphericity, density and flowability. Beside the well known standard alloys we offer a variety of special chemistries and make them available in the grain size distribution of your choice.

Wire

We offer Co-based STELLITE™ cored welding wires which set the industry standard. The material is available coiled on 15 kg K300 standard spools or 25 kg reels, in the most popular diameters from Ø 1,2 up to Ø 3,2 mm.

Rods & Electrodes

The rods are cast using a multi strand continuous casting process and are available in standard sizes from Ø 2,5 up to Ø 8,0 mm. The lengths vary from 350 mm up to 4 meters.

Welding Processes

Welding rods used for TIG welding are also used for hardfacing with the oxy-acetylene welding process. With the correct operation, a very low level of iron dilution can be achieved in the overlay.

Rod is available in these standard diameters:

- 2,6 mm (3 / 32") (special order)

- 3,2 mm (1 / 8")

- 4,0 mm (5 / 32")

- 5,0 mm (3 / 16")

- 6,4 mm (1 / 4")

- 8,0 mm (5 / 16")

These diameters are not available for any alloys. Special sizes on request.

MMA welding is still a widely used hardfacing process. In this process, an arc is drawn between a coated consumable electrode and the workpiece. The metallic core is melted by the arc and is transferred to the weld pool as molten droplets.

Electrodes are available in these standard diameters:

- 2,6 mm (3/32") (special order)

- 3,2 mm (1/8")

- 4,0 mm (5/32")

- 5,0 mm (3/16")

- 6,4 mm (1/4")

Electrodes are supplied in lengths of 350 mm (14”) and are boxed in 5.0 kg (11 lb) boxes.

In these arc welding processes, consumable hardfacing wire is fed continuously from a spool through the welding torch into the arc, where it is melted and transferred to the workpiece. Wire is also used as the hardfacing consumable in the Submerged Arc Welding (SAW) process. In this process, a mineral-based fluxing powder flows around the consumable wire and is melted by the arc.

Electrodes are available in these standard diameters:

- 1,2mm (0.045") — supplied in 15 kg (33 lb) spools

- 1,6mm (0.062") — supplied in 15 kg (33 lb) spools

- 2,4mm (0.093") — typically supplied in 25 kg (55 lb) spools

(optionally in 15 kg spools) - 3,2mm (0.126") (special order) — supplied in 15 kg (33 lb) spools

A specially-designed oxy-acetylene torch is used for powder welding. The workpiece is heated with the torch, powder is introduced into the gas stream from the integral powder hopper and transferred to the workpiece through the flame.

Powder Welding powders are available in these standard size ranges:

- KS 20–63 μm

- KX 20–106 μm

- K 20–75 μm

The PTA process is easily automated, providing a high degree of reproducibility of the weld overlays. Because the hardfacing materials are in powder form, it is possible to produce overlays from many different materials and combinations of materials with a wide range of hardnesses and other properties.

PTA hardfacing powders are available in these standard powder particle size ranges and custom sizes upon request.

- WM53 –180μm

- WE 63 –180μm

- E 53–150μm

- G 38 –125μm

- HK 63–210μm

- W 63 –150μm

When overlaying with a laser, an optical arrangement is used to focus the laser beam on the workpiece and heat it. Simultaneously, hardfacing material in the form of powder or wire is introduced into the laser beam and melted.

LASER hardfacing powders are available in these standard powder particle size ranges and custom sizes upon request.

- WM53 –180μm

- WE 63 –180μm

- E 53–150μm

- G 38 –125μm

- HK 63–210μm

- W 63 –150μm

Additive Manufacturing of metallic parts based on a powder-bed technology, such as Selective Laser Melting, Electron Beam Melting or Binder Jet Method, require special specification of the powder used for the processes.

- Our standards cuts AM applications are 45/10 μm and 38/10 μm

- Customized chemistries and grain size distributions are possible on special request

Thermal Spraying

In the Plasma Spraying process, powder is softened or melted in the plasma gas stream, which also transfers the particles to the workpiece.

- For availability of powders we refer to our catalogue downladable below on this webpage

In the HVOF process, powder is introduced axially into a chamber in which a gas flame is constantly burning under high pressure. The exhaust gasexits through an expansion nozzle which produces a high-velocity gas stream. The powder particles are heated in this gas stream and transferred by it with high kinetic energy to the surface of the workpiece, forming a dense coating with excellent bonding properties.

- For availability of powders we refer to our catalogue downloadable below on this webpage

Spray and fuse is a two-stage process, the powder alloy being deposited first by flame spraying and then fused. During fusing, the deposit is partially remelted and allowed to resolidify.

- For availability of powders we refer to our catalogue downladable below on this webpage

Brochure

Contact us

More about Cladding Consumibles