Investment Casting

Whether air or vacuum cast, a tight control is maintained over the foundry process to ensure part quality and consistency

Air casting is for specific alloy types such as steels or cobalt based alloys. Deloro Microfusione cast parts in air where the design and alloy allow. This is usually for low weight structural airframe or engine components. Metal is melted under an inert gas “blanket” to minimize oxidation during the foundry process. Molds are placed over the molten alloy in the crucible, this is then rolled over at a controlled speed to cast the parts. This is a fast low cost way to make high precision complex parts that meet our customer needs.

Vacuum casting is reserved for our superalloyed parts or where the design requires it. Here the metal is melted and poured under very low pressure to ensure no oxidation occurs at any point of the foundry process. The 2 Retech casting units we have are twin chamber design so that the alloy can be melted and stabilized before the mould is introduced via the second chamber. We can cast parts to over 100kg by this method or if the design has very thin section to be made. This ensures a controlled process for the part and the very best of quality.

Click here to read more about casting technologies offered by Deloro

The Investment Casting Process

Wax pattern injection & 3 D Printing

The Investment Casting Process (lost wax) begins by injecting melted wax under high pressure into a metal die (typically made out of aluminum), in order to achieve a wax pattern of the part required by the customer. If the part has internal channels for cooling or weight reduction, ceramic cores are positioned inside the metal die and the melted wax will be injected around the core. The ceramic cores are removed after casting through a chemical leaching process. For parts with complex shapes, Deloro Microfusione has established production operations with its in-house 3D wax printers. These are useful in order to create small-medium size wax printed patterns, with a geometry too complex for the standard injection in metal die. Also, wax printing has been used to reduce development time for customers.

Wax assembly

The wax patterns, after various checks (x-rays, dimensional and ultrasonics) and preparation, are assembled in a “tree” or “cluster”, constituted by the wax models, through a feeding system and through a cup by which the alloy will be poured.

Shelling (slurry and stucco coating)

The next phase involves the building of a ceramic shell around the wax cluster, obtained by dipping the wax assembly into ceramic slurries. The achieved layer is covered with sand dropped on the wet surface of the assembly.

The operations described are at different times and between each layer there is a waiting time dedicated to drying. So, the final shell is built by several layers and their number varies until the desired shell thickness is obtained. At Deloro the use of an automated full robot shell system for the building of the ceramic mold and daily/periodical checks on the slurries guarantee repeatability and stability of the process, improving process control of the critical first ceramic shell dips and increasing productivity in the area, with both a time saving and freeing up personnel for other critical areas

Dewaxing and Pre-firing

After the building of the ceramic shell, dewaxing and pre-firing follows by removing the wax from the mold, (leaving the internal cavity empty for metal casting) and in order to increase the mechanical properties of the mold through the sintering of the refractory materials.

At Deloro there are some operations done to check and evaluate the internal quality of the ceramic shell and in order to prepare the ceramic mold for the metal casting.

Casting

After pre-heating the ceramic mold at high temperature, the molten metal is poured inside the mold and then it is allowed to cool and solidify. Deloro Microfusione performs equiax casting, using furnaces in air and vacuum furnaces, with a pouring capability up to 160 kg. The alloys poured are stainless steel and Nickel and Cobalt based superalloys.

Shell Knock-Out and Parts Cut-Off

After cooling, the ceramic shell is removed using different processes (for example vibrations from a pneumatic hammer or knock-out with pressurized water) and the pieces are then separated from the feeding system with gate removal operation. For these final stages of cutting and gate removal, Deloro has installed an automated robotic cell used for large parts, obtaining advantages in precision of the cut and reducing handling problems. CNC grinding can be completed where complex shapes need to be restored under a gate.

Core Leaching

After cutting, any parts with a ceramic core are put in one of our 2 medium pressure vessels where, a caustic solution is able to remove the ceramic core through chemical leaching. This enables us to process the most complex of internal passage designs.

Finishing

At this point there are different finishing stages, useful for obtaining finished parts conforming to the customer's specifications from a shape and surface finish point of view, followed by heat treatments needed for obtaining the appropriate mechanical properties and hardness.

NDT (Non Destructive Testing) Inspections

Finally, the process is completed by a series of non-destructive tests i.e.:

- Fluorescent Penetrant Inspection (FPI), done for intercepting defects on the surface of parts

- X-rays, done to identify defects inside the pieces

- Dimensional check, where the conformity of the pieces from a dimensional point of view is verified

- Final visual inspection

In order to improve the quality of dimensional checks, Deloro has recently installed a 3D blue light scanning machine, which speed up the control operations and increase the precision of the check. After these tests, the full conformity of the finished parts is certified, and the castings are ready to be shipped to the customer.

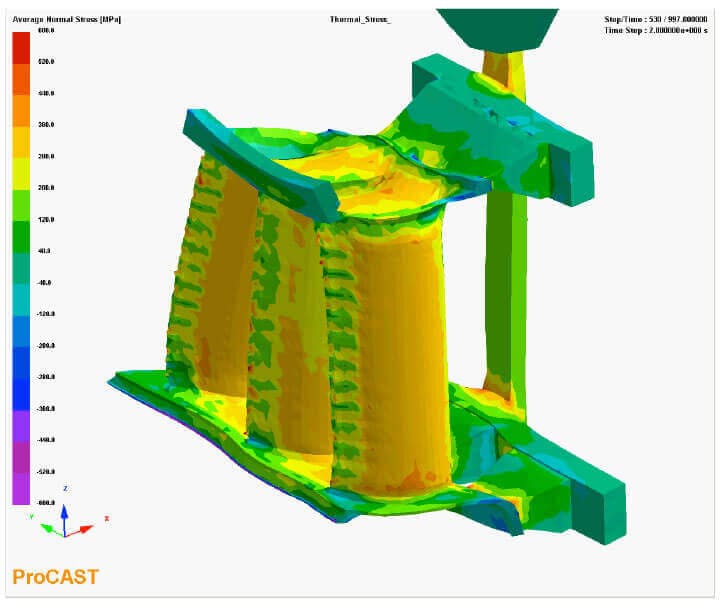

Solidification Modeling Capabilities

ProCAST is a computer simulation program for casting. It is based on a finite elements method computation. It is possible to create hypotheses and test them on physical development in advance.

ProCAST reduces time and scrap in the new products development. With this asset, Deloro Microfusione align the internal equipment to what is considered an high standard industry for engineering trials and developments. This addresses customer needs for first time.

ALLOYS

Maximum pouring weight 180 kg in vacuum.

• Inconel* 718

• Inconel* 738

• Inconel* 792

• Inconel* 939

• René* 80

• René* 108

• MarM 247

• Alloy 247

• Udimet* 500

• Alloy C 263

• Alloy C 1023

• Hastelloy* X

*Inconel and Udimet owned by Special Metals Corp, René by GE, Hastelloy by Haynes Int.

- FSX 414

- X40

- X45

- Stellite™

• 17-4 PH

• N 155

Other alloys if requested available, e.g. Delfer™B, Delcrome™, Norem*