Deloro Microfusione

Pieve Emanuele, Italy

Deloro Microfusione is a leading manufacturer of air and vacuum investment castings for industrial gas turbines (IGT) and aerospace applications. Deloro Microfusione specializes in stainless steel and a variety of nickel and cobalt-based super alloys, operating one of the largest vacuum melting furnaces for investment castings in Europe. The company’s 200 proud employees are headquartered in Pieve Emanuele, Italy.

Deloro Microfusione supplies components in stainless steel and a variety of Nickel and Cobalt based super alloys. Deloro Microfusione can offer a wide range of post casting value added services that may include hipping, heat treatment and machining. Deloro Microfusione has a long-time business relationship with Original Equipment Manufacturers (OEM) for Industrial Gas Turbines (IGT), Aerospace and other industries like General Electric Power and Water, General Electric Oil & Gas, Ansaldo, Siemens, GE AVIO, Leonardo, SAFRAN Group.

Deloro Microfusione´s Vision is to be the preferred challenger to the major players for medium-volume super alloy castings, balancing customer and industry exposure to smooth market volatility.

Deloro Microfusione´s Mission is to build value for our OEM Investment Casting customers by offering

- Best in class «time to market» for new products

- Reliability, quality and flexibility in manufacturing

- Openness to new technologies and innovation

Balancing customer and industry exposure to smooth market volatility, Deloro Microfusione has a long tradition for investment casting components for various applications including turbochargers, commercial, oil&gas, automotive, generic industrial.

We value Passion, Transparency, Solution Orientation, Responsibility, Safe Working Environment.

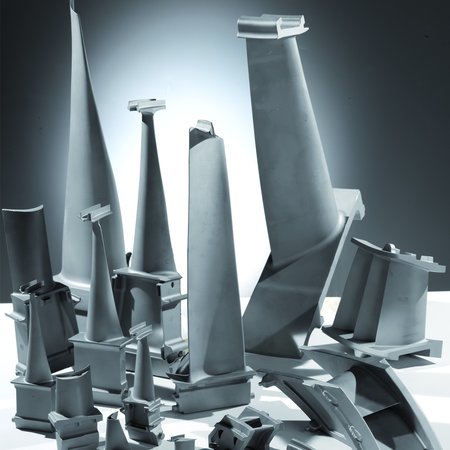

Products

Deloro Microfusione started producing IGT structural parts in Ni and Co superalloys in mid 1970’s and rotating blades since the 1980’s. With pouring capabilities up to 160 kg (gross), Deloro Microfusione can cast fairly large equiaxial components, both cored and non-cored.

Production includes all components available in the hot gas path of the engines:

- Turbine blades

- Turbine nozzles

- Heat shields

- Burners, swirlers and combustion chambers related components

Deloro Microfusione is familiar with the most common engines and demanding products like complex cored blades and other H-class components.

Deloro Microfusione specialises in small to medium size structural and non-rotating aerospace components as well as on parts for the defence industry since the 1980’s.

Production includes engine and frame components both for civil and military programs, including:

- A320/321

- CFM56

- EFA-EJ200

- EH101

- TP400

- M88

- SAM146

- PW4000

- V2500

Deloro Microfusione has developed over many years a deep understanding of investment casting complex nickel and cobalt based super-alloyed components for a wide variety of industries. Deloro Microfusione investment casting process has been developed to now cast product from less than 50g to over 100kg. We are now able to shell and cast complex shaped parts to reduce the need for machining. Also we make many products with internal cavities such as the complex cooling passages needed in today’s turbine engines.

Many processes have been either fully or semi-automated to ensure consistency and product quality. With our ability to work with rapid manufacturing methods such as wax and ceramic printing or rapid make tooling, allows us to respond to customers’ urgent needs. Deloro Microfusione continues to grow in experience and ability through our skilled team and technological innovation.

- Vacuum Investment Casting

Vacuum Casting Furnace – Retech 180 kg

Vacuum Casting Furnace – Retech 100 kg - Air Investment Casting

Roll-Over Induction Furnace (Air) (2x)

Foundry area includes 3 dedicated pre-firing furnaces.

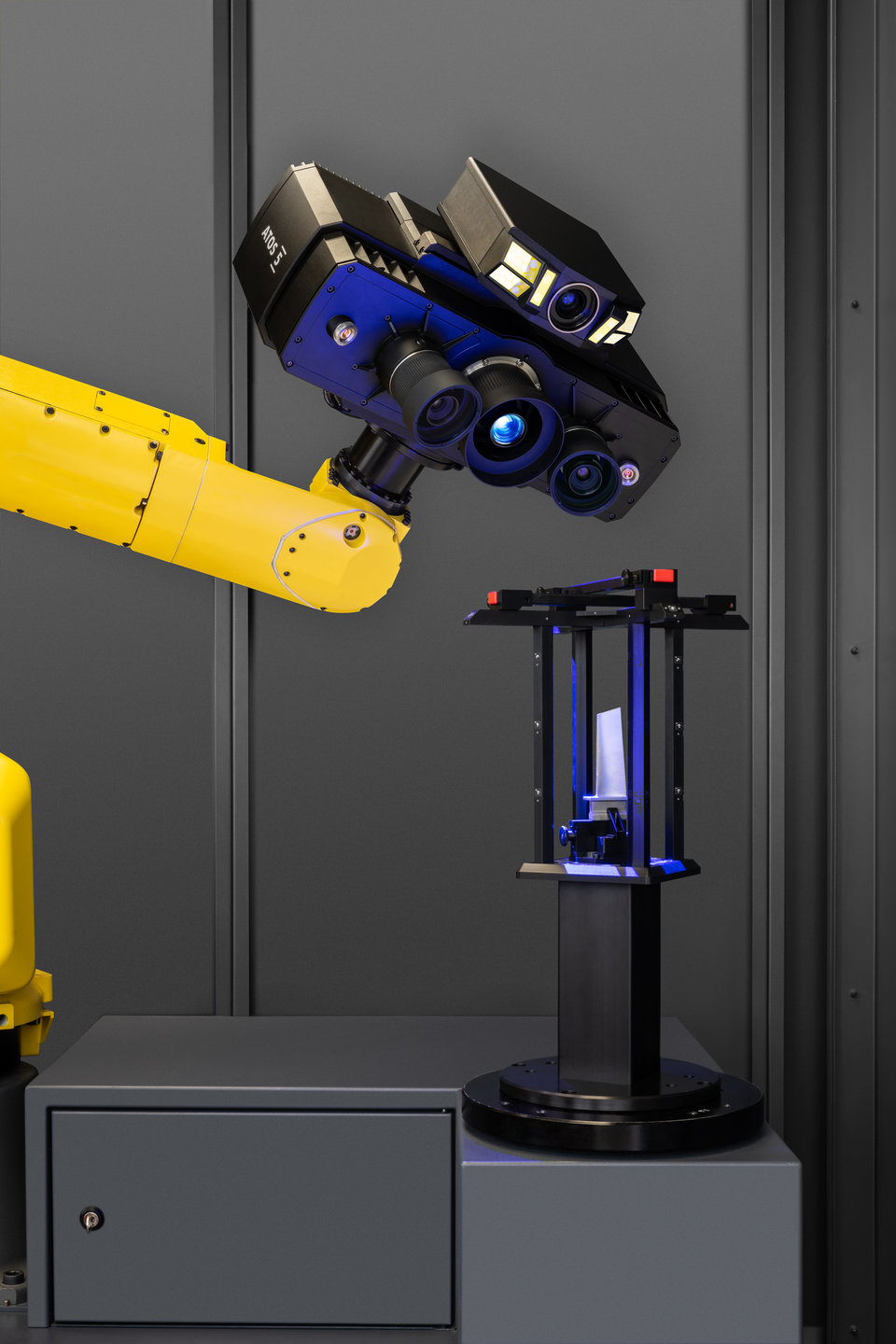

Research & Development

Deloro Microfusione sticks to the tradition of Deloro of continued Research and Development

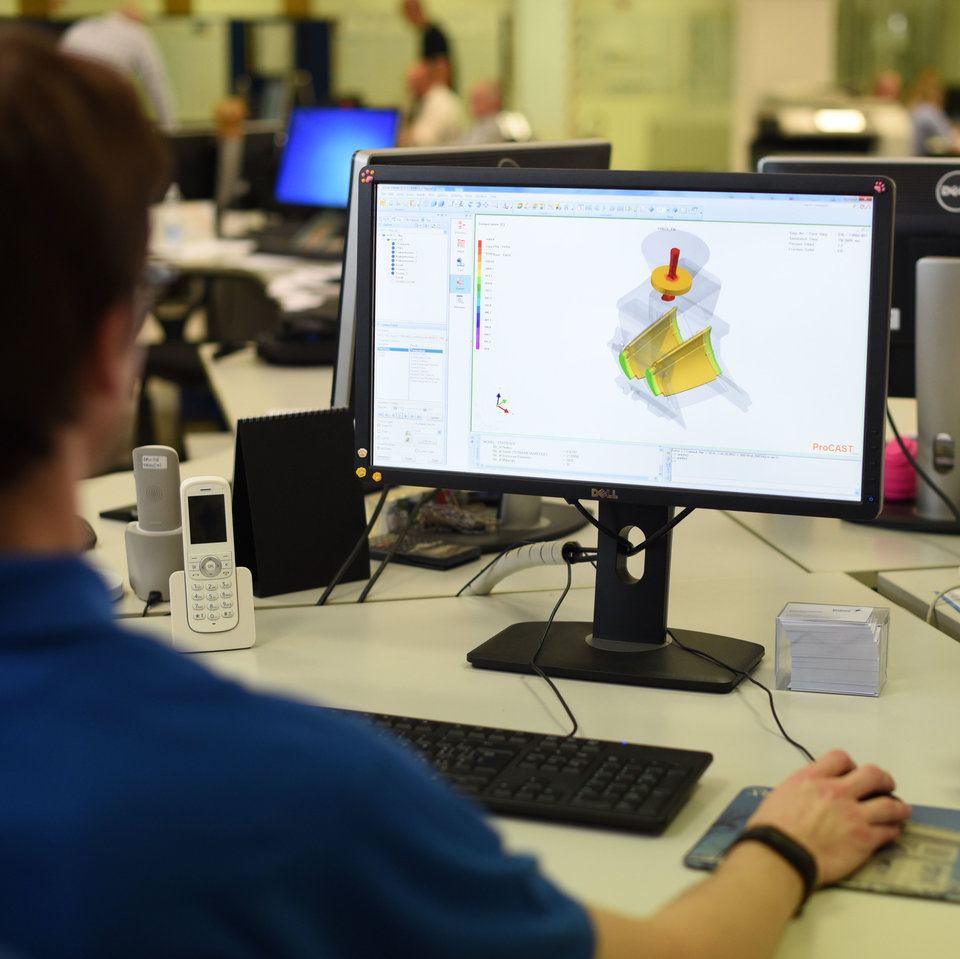

process. Our Research and Development Department is working on continuous improvement of products and processes. Dedicated resources are available to achieve the best cost effective processes in manufacturing of enhanced product characteristics. State of the Art design tools such as other 3D Cad systems, GOM blue light dimensional scanning and Procast solidification modelling software are used to develop sophisticated processes for wax patterns reforming, clusters assembly and casting.

The use of rapid prototype technology and provisional silicon shells ensure the very effective real-time implementation of preliminary tests on actual castings, before the final steel tool is built. Continous improvement methods are actively used with our customers in response to production feedback, identifying the most appropriate best possible procedures. Vacuum Heat Treatment and Hot Isostatic Pressing procedures are continuously upgraded on the basis of newly available technologies with the purpose of granting to our customers the best mechanical metallurgical properties of the products.

Deloro Microfusione has developed over many years a deep understanding of casting complex nickel and cobalt based superalloyed components for a wide variety of industries. Our product range includes customers from the automotive, oil and gas and turbine engine industries. DM investment casting process has been developed to now cast product from less than 50g to over 100kg. we are now able to shell and cast complex shaped parts to reduce the need for machining. Also we make many products with internal cavities such as the complex cooling passages needed in today’s turbine engines.

Many processes have been either fully or semi-automated to ensure consistency and product quality. Our workforce is trained to take on new machines and skilled tasks. Our vibrant lean activities would not be successful without the skilled input from all levels of the manufacturing to management team.

CERTIFICATIONS & QUALIFICATIONS

Deloro Microfusione holds various international qualifications and certifications:

- ISO 9001:2015 and EN 9100: 2018

- ISO 14001:2015

- PT and RT NADCAP accreditation

Deloro Microfusione holds also certifications of prime Aerospace customers and on annual basis, our Laboratory takes part to accredited Proficiency Testing activities for interlaboratory tests comparisons.

Moreover, in a view for a greater attention and protection of the environment with increasingly sustainable manufacturing activities, our company has also achieved, in 2018, the ISO 14001: 2015 Environmental Management System certification, an international standard with voluntary adhesion.

How to reach us ...

Deloro Microfusione S.r.l.

Via Giuseppe Di Vittorio 24

20072 Pieve Emanuele (Milan)

ITALY

+39 02 90787 1

milano.information@deloro.com

Contact us

More about Deloro Microfusione