Quality Management

Quality Assurance System for high quality products

For decades all Deloro Plants have had an established Quality Management System, to promote and guarantee awareness and responsibility to all our employees. We are committed to quality as well as the ISO9001:2015 certificates. All Plants have various certifications for industry standards, such as the NADCAP, ISO 9001, ISO13485 and the Pressure Equipment Directive. In addition, we hold various customer approvals for welding according to ASME VIII or RCC-M Standard.

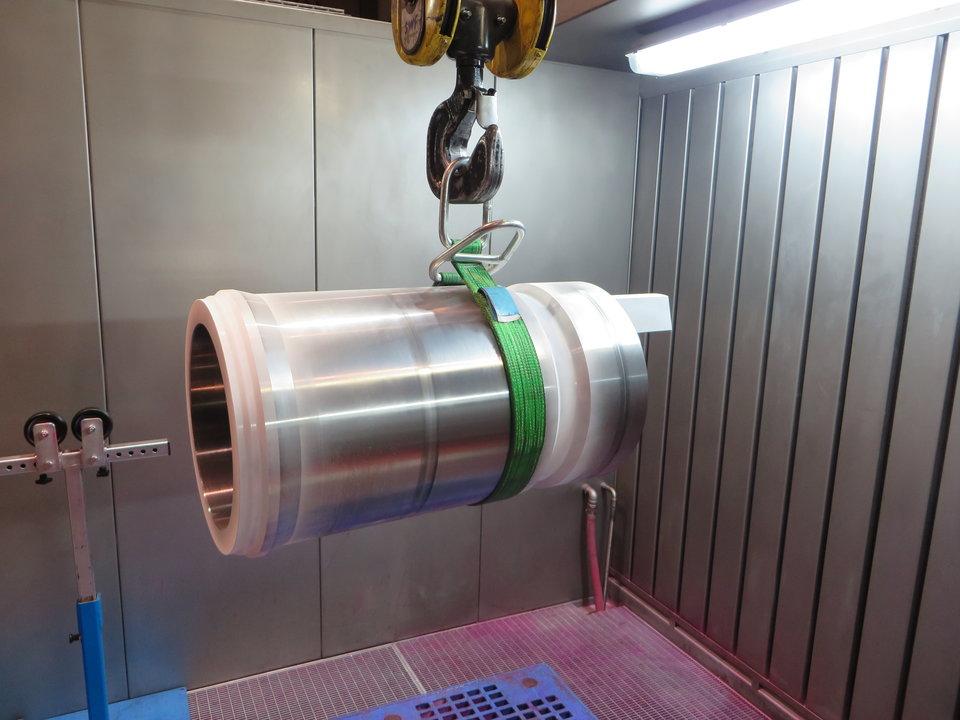

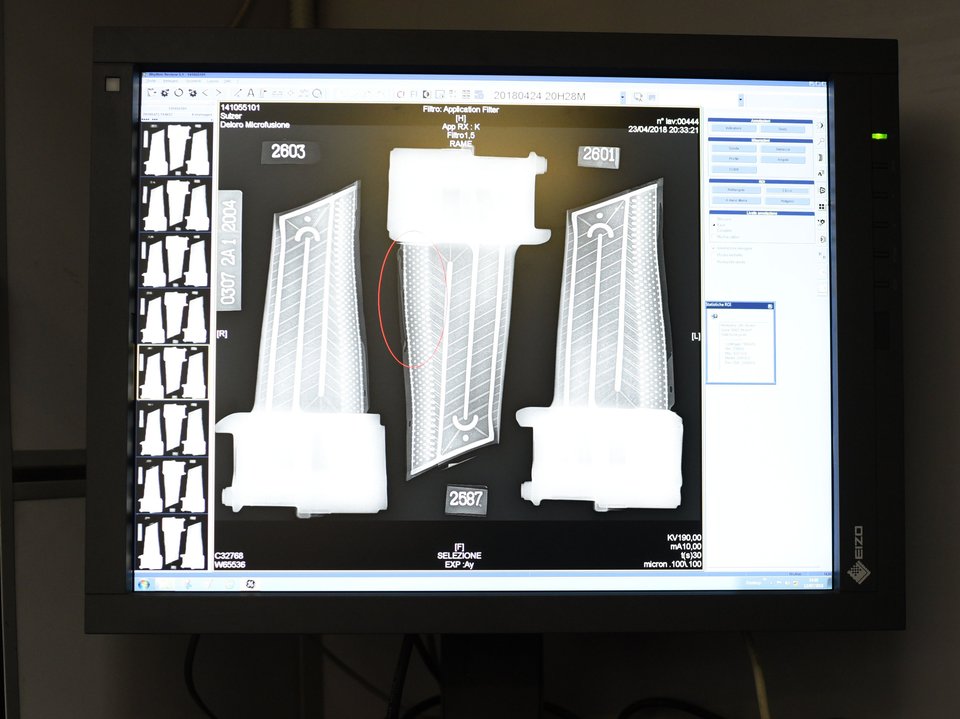

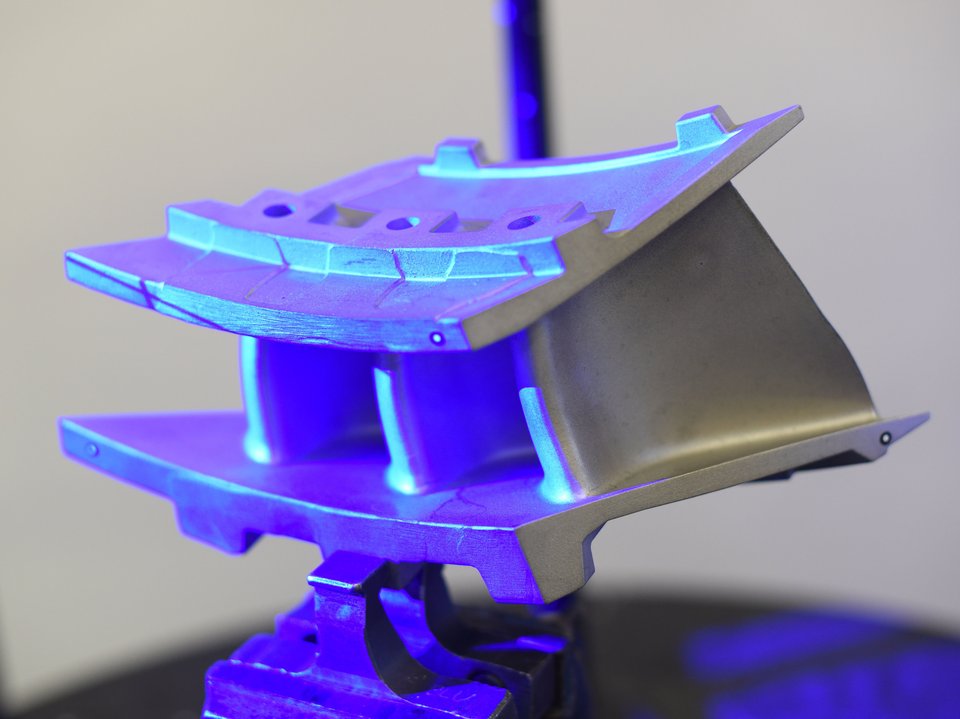

To improve our Quality Management and our processes and services at all times, we are investing in our equipment and personnel. Consequently, we can provide in our measuring and analytic laboratories for example modern digital radiographic or 3D-Microscope technologies. This is supported by top qualified staff for all dimensional measurements, chemical and metallurgical analyses as well as NDT-Inspections like PT, VT, RT, UT, MT.

Quality Testing & Laboratory

- Dye Penetrant Test

- Hardness Test

- Bend Test

- Micrograph & porosity inspection

- Outsourcing specific analyses to external laboratories

Digital X-Ray System

- Increased productivity in the area, cycle time saving

- Green technology removing the need for film and process chemicals

- Saving of data is more secure with back-up storage

- Ability to transmit to customer original data

- Rapid new process development between customer and ourselves

GOM blue light dimensional scanning

- Faster than conventional Co-ordinate Measuring Machine (CMM)

- Gives whole surface profile analysis versus original CAD model

- No mounting required so saving cost and set up time

- Non-contact measurement so delicate items can be checked

- Customers demand greater detail to achieve better engine efficiencies

Contact us

More about Quality Management