Wrought & Forged Stellite™

STELLITE™ 6B AND 6K

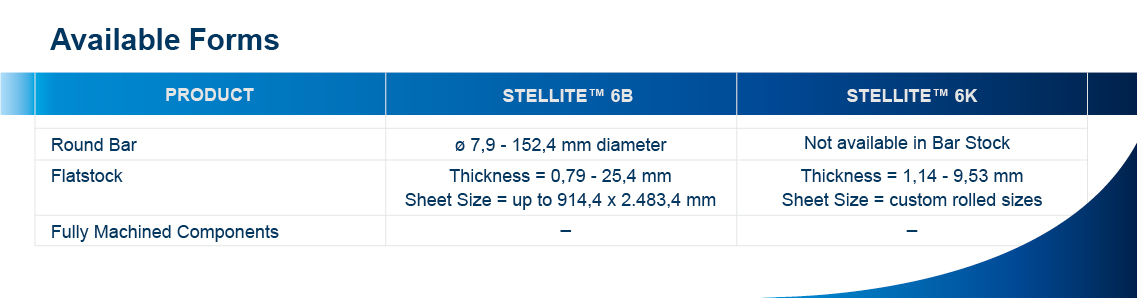

Stellite™ 6B and Stellite™ 6K are wrought materials whose physical properties are enhanced as the grain structure of the metal changes during plastic deformation. During this forming process, the wrought material achieves higher strength than cast material of the same chemistry. Stellite™ 6B is produced in both bar and sheet form while Stellite™ 6K is produced only in sheet form. These materials are then cut to shape (laser or water jet) and machined into components to a customer’s drawing.

Stellite™ 6B and Stellite™ 6K are available in sheets, plates and fabricated shapes. Stellite™ 6B is also available as round bar stock. Deloro Wear Solutions has the capability to provide components made of these materials to your exact specifications. For more information, contact us about our in-house machine shop capabilities.

Stellite ™ 6B

Stellite™ alloys are available in many different grades (chemical compositions) and several different processes or methods of manufacture. For wrought grades Stellite™ 6B and Stellite™ 6K, the wrought or hot forging method of production leads to improvements of the resulting material with regards to:

- Mechanical Properties

- Toughness

- Wear Resistance

- Corrosion Resistance

Stellite™ 6B is stocked in standard mill forms of flat stock ranging from 0,79 - 25,4 mm thick and round bar ranging from 7,9 - 152,4 mm diameter. Special sizing is available on request. Ask about our finish machined Stellite™ 6B components capability.

Stellite™ 6K

Stellite™ 6K has similar properties to Stellite™ 6B, but is slightly harder and less ductile. Stellite™ 6K is excellent for cutting or scraping applications, such as knives or scraper blades. Stellite™ 6K is a custom-rolled material and can be produced to a gauge and sheet size uniquely suited to your application. Stellite™ 6K is available in flat stock ranging from 1,14 - 9,53 mm thick. Ask about our finish machined Stellite™ 6K components capability.

Product Properties

Stellite™ 6B is resistant to the effects of seizing or galling. In many cases, its low coefficient of friction allows sliding contact with other metals without damage by metal pick- up. Stellite™ 6B has been used in equipment where no lubricants were used because of the nature of the product being handled. Sleeves made of Stellite™ 6B move smoothly, with minimum resistance, even when operating in contact with other metal parts. They have been useful in inaccessible areas where efficient lubrication is impossible. Sleeves and bushings have resisted seizing even when lubricants were diluted by gasoline, cleaning fluids and other liquids that wash out an oil film. They have operated at peak efficiency even when lubricants decomposed under heat or were destroyed by abrasive particles.

Parts made of Stellite™ 6B have a long service life, even under constant erosive conditions. This material has outstanding resistance to cavitation-erosion. The wrought structure results in improved abrasion wear resistance comparable to much harder cast materials. Stellite™ 6B used for steam turbine erosion shields has protected the blades of turbines for over 30 years of continuous service.

Stellite™ 6B retains high hardness, even at red heat. Once cooled back to room temperature, it recovers its full original hardness.

Stellite™ 6B combines wear and corrosion resistance with good impact strength and resistance to thermal shock. The toughness of the wrought alloy depicted by its charpy impact energy goes up almost four fold compared to the cast version.

High temperatures have little effect on the hardness, toughness and dimensional stability of these alloys. They are highly resistant to atmospheric oxidation at ordinary temperatures and have good resistance to oxidation at elevated temperatures.

In addition to wear resistance, Stellite™ 6B has good resistance to a variety of corrosive media. This combination of properties makes Stellite™ 6B particularly useful in such applications such as food- handling machinery, chemical equipment and others where both wear and corrosion resistance are necessary.

Wrought forms of Stellite™ 6B and Stellite™ 6K are supplied in the solution heat-treated condition, unless otherwise specified. The standard heat treatment is at 1.200°C followed by air cooling.

Brochure

Contact us

More about wrought products