WORLD-CLASS PTA WELDING SYSTEMS

The strength of Deloro Hettiger Welding Systems is to customize PTA welding equipment in close co-operation with our customers. We adapt our welding systems to individual needs and develop the processes for specific welding tasks. Easy to learn and easy to use Human-Machine-Interface, highest standards in machinery safety (European Machinery Directive 2006/42) and in combination with best of class quality, Deloro Hettiger Welding Systems sets the standard in PTA welding machines. With a vast product range of latest technology equipment and accessories for PTA welding, we offer tailor-made solutions for all application requirements.

We provide essential features for the technological and digital transformation of production processes!

Welding Systems

The BASIC LINE is designed for easy, safe and reliable manual operation and/or integration in existing handling systems.

For fully automatic welding processes our COMPACT LINE is the perfect solution with power source up to 350 A, standardized aluminum frame and single powder feeder.

A customized solution for your individual needs and applications is available through our PREMIUM LINE with power sources up to 500 A. The advantages of this process are customized steel frame and optional double powder feeder for individual powder handling.

For specific requirements of fuel engine valve cladding e.g. in the automotive and diesel engine industry, the VALVE LINE provides a fully automatic processing system.

Reliability and throughput of our torches and powder feeders will convince you day after day

The availabliity of spare parts and service works from our technicians will support you to maintain a high degree of welding system availability and productivity.

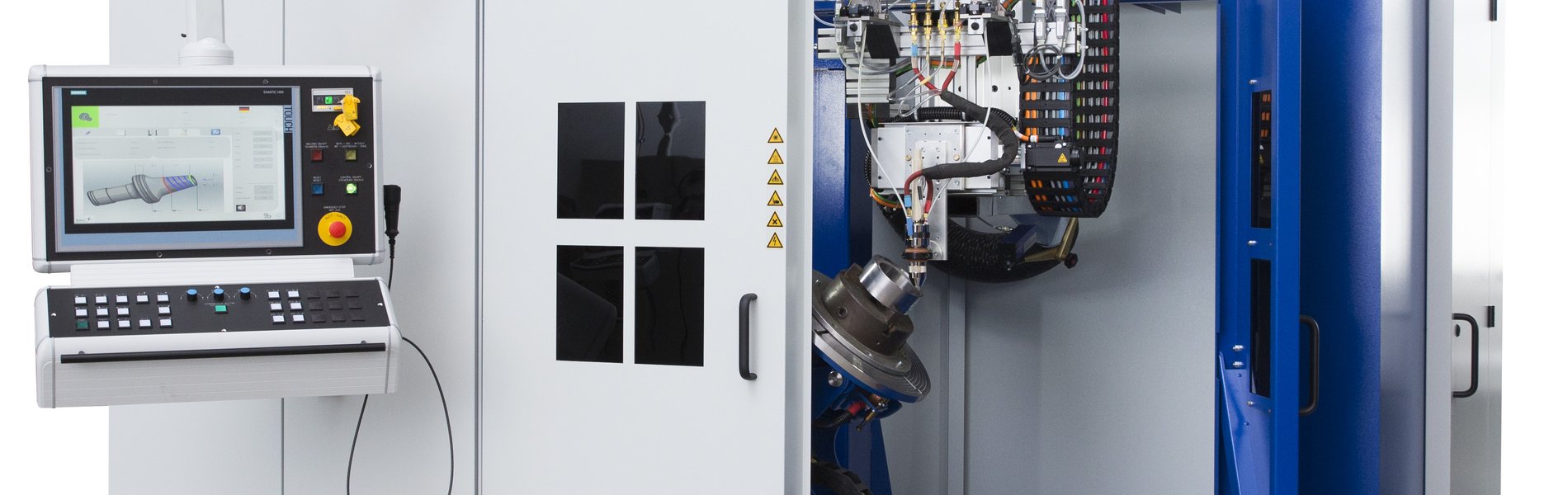

HUMAN-MACHINE-INTERFACE

System for easy operation

The Human-Machine-Interface consists of an intuitive-to-use touch screen in combination with a switch panel for redundant operation of axis movement, welding current and powder parameters. The interface provides various authorization levels for operator administration by personalized RFID-key to assure secure operation of system.

The easy to learn HMI interaction is supported by a graphic display of pre-selectable geometries and teaching procedures. This enables the operator to set up a welding process within the shortest time.

A strength of the Deloro Welding Systems software is that it controls the whole machine set-up through one central interface. Geometries und movement profiles for individual welding tasks can be added and welding documentation can be adapted to company requirements.

FEATURES and BENEFITS

- Easy-to-Use Human-Machine-Interface

Operator is intuitively guided through the set-up process - Easy Machine Set-up

By pre-selectable geometries, movement and welding profiles - Master-Slave Combination of Axis

Enables a fully automated welding of complex geometries - Parameter Tracking and Storage

Chronological process visualization, quality assurance and documentation - Telemaintenance via Internet

Reduction of service and maintenance costs at site

Brochure

Quality

Extensive quality systems assure that our product and process control meet your high expectations. Our facility maintains ISO 9001:2008 certifications and we hold numerous industry-specific qualifications. Our PTA welding equipment complies fully with the highest standards in machine safety in accordance with the European Machinery Directive 2006/42.