VALVE LINE

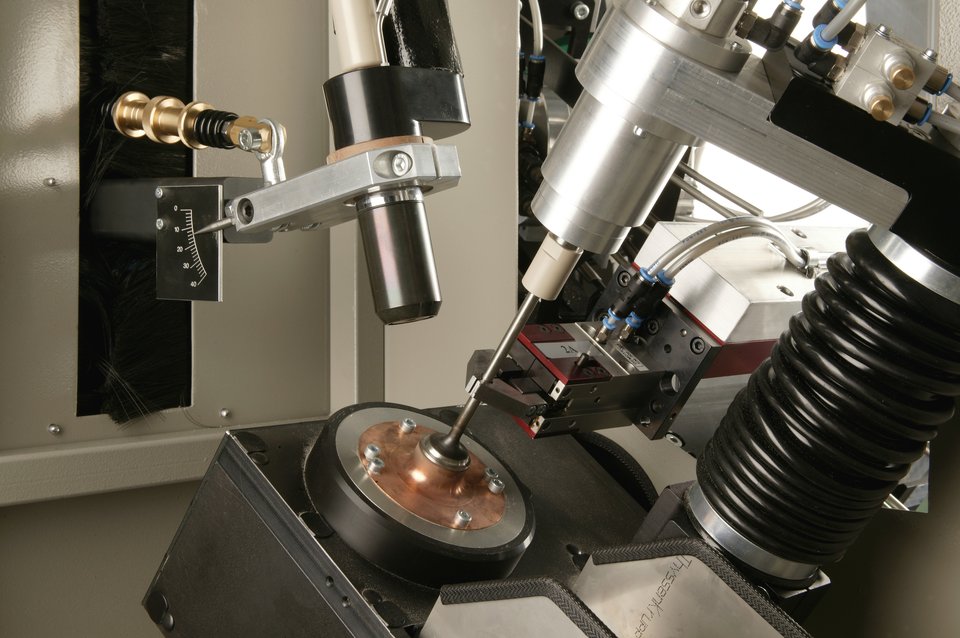

PTA powder cladding system for fuel engine valves

The VALVE LINE provides a fully automatic processing system for the specific requirements of fuel engine valve cladding. Designed for the automotive and diesel engine industry and tailored to the individual welding task, a wide range of valve dimensions can be processed. This high-quality and reliable welding solution provides integrated torch and workpiece manipulation and other customized features controlled by a central PLC.

The VALVE LINE has been installed at many manufacturers plants of valves around the world and has proven its reliability, productivity and superior cladding quality.

The specialized design combines all necessary hardware components in a robust steel frame. Easy operation is ensured by an integrated operation panel and PLC which controls all functionalities for execution of the cladding process. This includes welding parameters as well as valve loading and unloading.

Easy operation is ensured by an integrated operation panel and PLC which controls all functionalities for execution of the cladding process. This includes welding parameters as well as valve loading and unloading.

FEATURES and BENEFITS

- Power Sources from 100A - 350A

Individual selection of suitable power supply - Machine Torches

Deloro Hettiger Welding designed torches for outer diameter cladding - Powder Feeder

Well-proven and reliable gravity wheel feeder - Electronic Mass Flow Controllers

Reliable gas management for automatic welding integrated in the Programmable- Logic-Controller (PLC) - Welding and Manipulation Axes

Rotational mechanical axis for welding of seats with oscillating and pneumatic axis for loading / unloading - Loading and Unloading of Parts

Optional manual or automated loading

Contact us

More about VALVE LINE