Brief History

Deloro Stellite rose like a Star

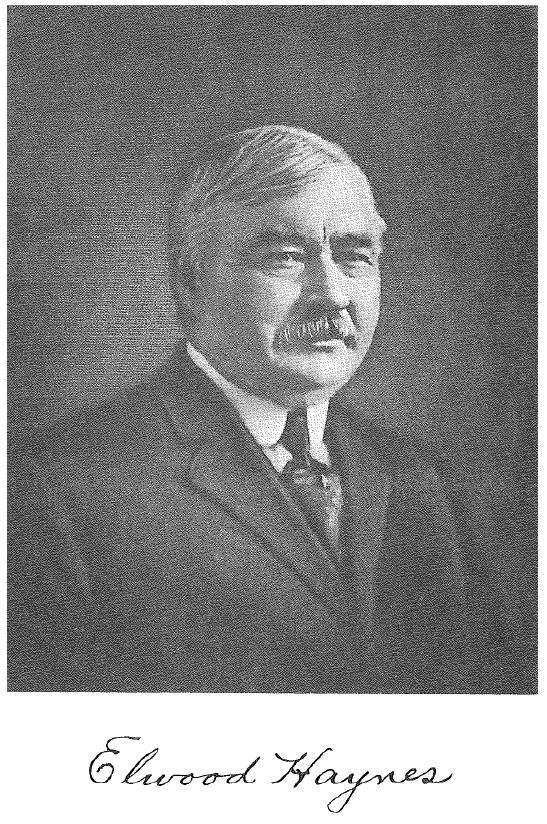

The history of Deloro started in 1868 in Deloro, a small gold mining village in Ontario/Canada. The Goldmines of M.J. O’Brien produced—in addition to gold—very clean Cobalt. Around the same time, Elwood Haynes worked in Kokomo, Indiana/USA, on Cobalt based hard metals. He called his discovery Stellite®, derived from the Latin word “Stella”, for star.

1907 The first patent (no. 873,745) was granted to Elwood Haynes.

1910 Licensing agreement reached between Haynes and Deloro Smelting and Refining Company of Deloro Ontario

1912 Queen´s University metallurgist H.T. Kalmus developped a process for creating cobalt metals and Deloro Smelting & Refining Company produced the first Stellite alloys; Stellite tool metal revolutionized the metalworking industry – the wonder metal!

1914 – 1918 Industrialization of the alloys within the first world war, used for machine tools especially by engine manufacturers (trucks & cars, liberty aircraft, armaments)

1919 - 1930 Expansion to Europe, first factory in England (Swindon), Expansion of Canadian facility, hardfacing services offered to customers

1939 – 1941 Canadian facilities expand to include investment casting

1945 – 1955 Increase of demand for Stellite wear resistant alloys in all major industries to prevent premature failure of metal components

1948 Microfusione Italiana was established as investment casting facility in the city of Milan

1956 – 1972 Deloro Stelllite left its original site in the village of Deloro and relocated to Belleville, Ontario, Canada; Flux cored Stellite wire production commenced in Swindon, UK

1970´s First IGT structural parts with Nickel and Cobalt superalloys produced

1972 Stellite was implemented in Koblenz, Germany - as third manufacturing plant and as distribution point for welding products and hard-surfacing service center. Today known as Deloro Wear Solutions GmbH.

1972 – 1985 Expansion of Deloro Stellite, 4th factury in Goshen, Indiana, 5th facility in Shanghai, China. Dedication to metal powder production for hard-surfacing, manufacture of equipment using powders produced. Acquisition of new thermal spray coating technology, improvement of design and function of Plasma Transferred Arc Equipment, improvement of torch designes for heavy duty applications for valves and feed screws, Process and Product Services;

1985 – 1999 Process and Product Expansions in various segments, rolled and forged components, powder metal component production, first IGT blades produced at Microfusione

1999 – 2012 Expansion into new regions and technologies through the integration of the Microfusione investment casting business and various regional coating shops.

2001 The portfolio of Microfusione was restructured to concentrate on IGT and Aerospace market

2006 First complex core blade manufacturing

2012 Deloro Stellite Group is acquired by Kennametal Inc.

2013 First F-class blade qualification achievement for Microfusione

2015 The European Businesses of Deloro are sold to Madison Industries and became independent again, starting to grow the business, rebuild technology and sales strength and continuing the mission to make the world safer, healthier and more productive.

2016 Microfusione achieved the first H-class part qualification

2022 With the sale of the Deloro Group to a US-American entrepreneurial family whose professional roots and passion also lie in metal processing, Deloro was able to set the course for future-oriented growth.