Metallurgical Expertise & Material Selection

Stellite™, Deloro™, Nistelle™, Tribaloy™ and other specialized alloys

The name Deloro Wear Solutions has reflected for many years the know-how and specialization in high-performance alloys, which excel within severe service conditions of wear, corrosion, and/or high temperature. We at Deloro Wear Solutions derive the color of our star from cobalt blue (CoAl2O4), as all things cobalt-, nickel-, and iron-based are our passion.

Metallurgically, cobalt is a main alloying element in wear-resistant, corrosion-resistant, and heat-resistant alloys. Generally, cobalt-based alloys are categorized into four main families based on the strengthening mechanism: solid-solution, carbide-strengthened, intermetallic-strengthened, and the newly developed high-entropy cobalt-base alloys. Additionally, cobalt forms together with nickel a wide range of heat resistant alloys, which are often used for gas turbine vanes and within the aerospace industry. Moreover, cobalt is used as bond material in WC-Co cemented carbides (Cermets), Stelcar alloys, and HVOF powders for optimum abrasion resistance under harsh conditions.

Cobalt-base alloys are a unique combination of alloying elements, in which each element plays a vital role. Chromium imparts corrosion and oxidation resistance. Nickel stabilizes the FCC crystal structure and enhances the mechanical properties. Molybdenum and tungsten act as solid-solution strengtheners, carbide formers, and/or form together with Cr, Si, and Co intermetallic compounds, which add more wear and high-temperature resistance to the alloy.

Whatever your needs are, you will find a suitable solution for it either in our Stellite™, Deloro™, Tribaloy™, Nistelle™, Delcrome™, Stelcar™, JetKote™ powder, or even a specially modified/developed alloy tailored to fulfill your individual application requirements.

Stellite™

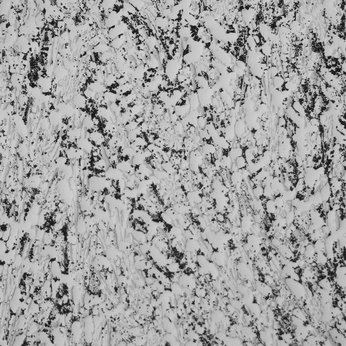

Stellite™ alloys are divided into solid-solution, hypo-eutectic, and hyper-eutectic based on the carbon content. Solid-solution alloys offer excellent corrosion, oxidation, and high-temperature resistance. For this reason, Stellite™ 25 is used in gas turbine and aerospace parts. Ultimet ™ possesses very good resistance to localized corrosion (pitting and crevice corrosion), many aggressive environments, and exhibits excellent wear properties in terms of slurry erosion, cavitation erosion, and galling. Furthermore, both Stellite™ 25 and Ultimet™ are qualified by NACE MR0175/ ISO 15156-1 (Materials for use in H2S-containing Environments in oil and gas production). For cryogenic application, Stellite™21 is used for critical valve parts, which should serve under high wear rates.

Increasing the carbon content in Stellites, enhances the carbide formation in the alloys and introduces the hypo- and hyper-eutectic categories. Stellite™ 6 was one of the earliest developed hypo-eutectic Stellite™ alloys and is used for wear plates and bars, bushings, and sleeves for shafts operating in hot or possibly corrosive atmospheres where lubrication is difficult or impossible. Many design challenges regarding wear generally, and abrasive and slurry-erosion wear especially were solved by choosing Stellite™ 3 (hyper-eutectic), Stellite 4™ , Stellite™ 6, Stellite™ 12 (hyper-eutectic), Stellite™ 20 (hyper-eutectic), which makes Stellites the first-choice candidates in many industrial fields.

Tribaloy™

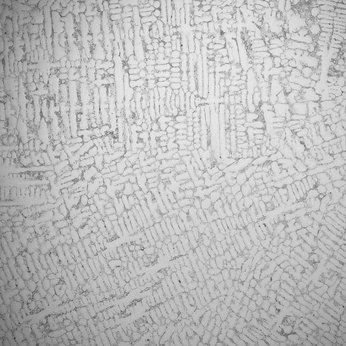

Today, we can’t image the growth and new performance levels within the automotive industry without the invention of the Tribaloys. Tribaloy™ alloys, with either cobalt or nickel bases, are developed for applications in which extreme wear is combined with high temperatures and corrosive media in the absence of lubrication. Their high molybdenum content accounts for excellent adhesive resistance (metal-to-metal) up to 800 - 1000 °C, due to the formation of the Co/Ni-Mo-Cr glazed layer.

Nistelle™

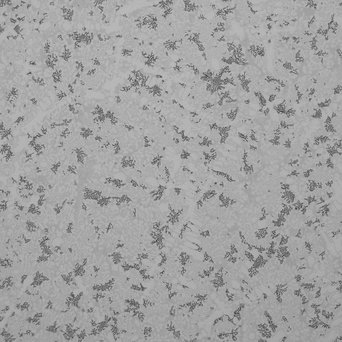

Nistelle™ alloys are widely used in oil and gas applications, flue gas desulphurization and pharmaceutical and chemical processing industries, where corrosion is the main design challenge. Nistelle™ alloys offer an outstanding resistance to uniform corrosion attacks, localized corrosion, stress corrosion cracking, and oxidation. Like the cobalt-base alloys, molybdenum and chromium define the alloy characteristics and add a unique resistance to non-oxidizing acids, chlorides, and high-temperature. Besides, Nistelle™ alloys are well-known for their excellent pitting and crevice corrosion resistance, and ease of fabrication and welding.

Deloro™

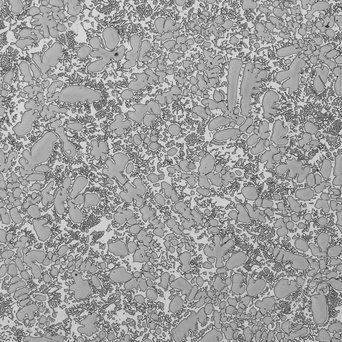

Deloro™ alloys are nickel-based and are usually designed within the Ni-Cr-B-Si system. They cover a wide range of hardness from relatively soft, tough, built-up alloys that are easily machinable to exceptionally hard, wear-resistant alloys. They can be chosen within a hardness range of approximately 20 to 60 HRC depending on the application. The lower hardness Deloro™ alloys are, among others, typically used for glass forming molds and nuclear applications when wear resistance is required from a cobalt-free alloy. The higher hardness Deloro™ alloys are used in severe wear applications and they can even be blended with carbides for maximum hardness. They maintain their properties up to temperatures of about 700 °C and offer good oxidation resistance.

Delcrome™

For lower application temperatures and moderate corrosive mediums our Fe-based Delcrome™ alloys are mainly used against abrasion for parts used in the mining industry, oil and gas, and structural parts. Deloro also offers a wide range of biomedical Co-base alloys such as ASTM F75 and Ni-free dental alloys which are widely used for manufacturing of implants owing to their human body biocompatibility, corrosion resistance, wear resistance, and their interesting mechanical properties of strength, ductility, and high-cycle fatigue strength

Our material portfolio is further enhanced by customized modifications of established alloys to offer tailored solutions for specific customer needs and applications.

Our Materials Technology Team continuously works on developing modern alloy designs, using state of the art thermodynamic tools to modify and improve our existing alloys and to develop new ones. This allows us to sustain and expand our range of material solutions, which ultimately increase your efficiency.

We at Deloro are pleased to offer our customers the benefits of our experience and know-how, high quality levels, and precision parts and components covering many industrial fields such as mechanical engineering, the automotive industry, aviation, new energy, food technology, metal, and the petrochemical industries.

Many of our customers are recognized as leaders in their fields. Moreover, we provide, based on our long years of experience with wear solutions, assistance, flexibility, and problem analysis to help our customers find the most suitable, sustainable, prompt, and economically effective material/solution for their application.

For more information, please contact us:

Contact us

More about Metallurgic Expertise