You need to improve your wear-, elevated temperature- and/or corrosion resistance of your product? Just add a little Deloro® to it!

Now you can literally do this by using Additive Manufacturing (AM)!

Making our alloys available for 3D-printing literally allows to proceed in a whole new dimension. Additive technologies allow more complex geometries, smaller batch sizes and give us the possibility to make us and our clients able to actually grasp new designs and parts in a relatively short time and with a higher cost effectiveness. AM methods are well-equipped to build up whole parts layer by layer or add functional and protective coatings right where they are needed.

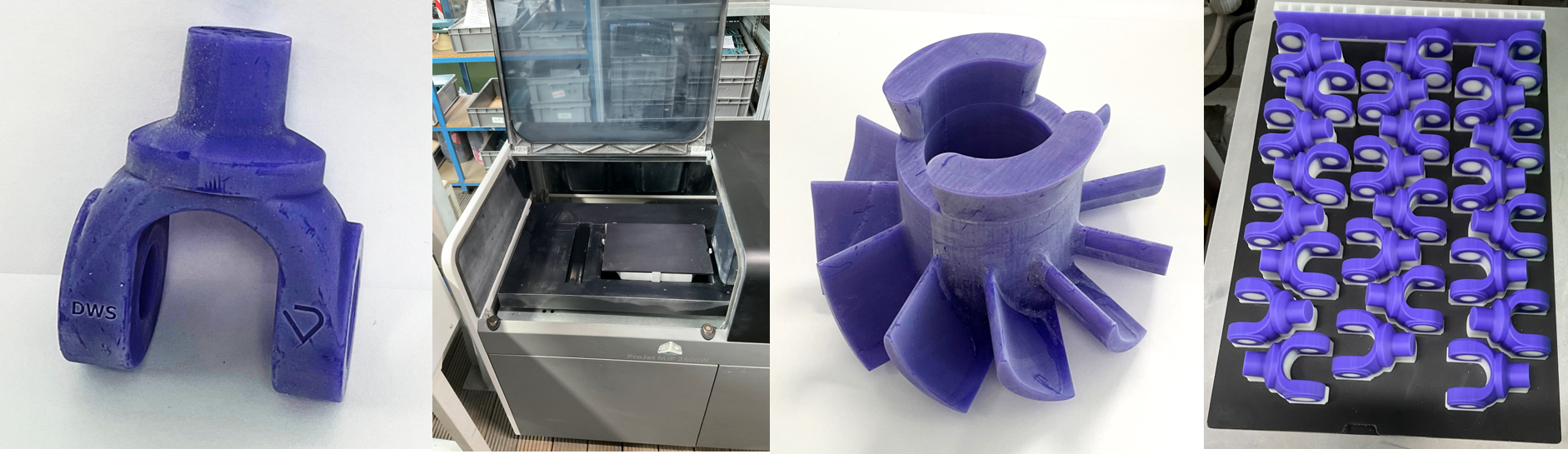

We are already experienced with the mindset of 3D-printing by employing our 3D-Waxprinter to produce prototypes and small batches for investment casting. This allows us to cast fresh design ideas without the cost- and time consuming production of a tool and makes small batches of a part possible.

The technologies used for AM with metals are numerous and @Deloro we are already using such as PTA and Laser cladding at our Deloro Wear Solutions facility in Koblenz, Germany and Deloro Coatings facility in Italy. Printing technologies as Selective Laser Melting (SLM) or Metal Binder Jetting (MBJ) could not be used successfully with our strongest alloys Stellite™ 21, Stellite™ 6 or Tribaloy™ T-400 because of the brittleness they exhibit already in conventional processes. The rapid cooling and iterative formation of 3D printing leads to even finer structures which result in still stronger and more brittle materials properties. Unless you can control and steer them…which now we can!

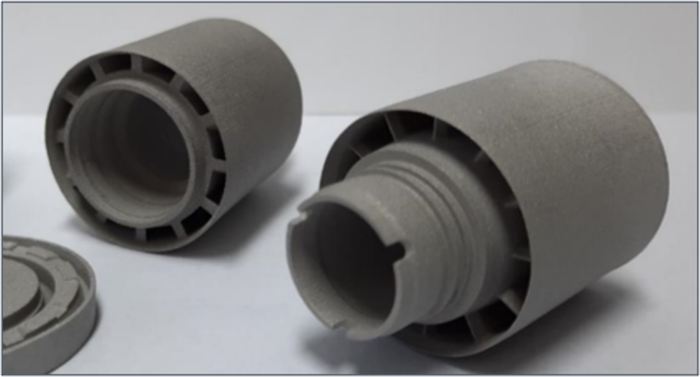

In partnership with Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen (Germany), Deloro® developed the printing and sintering processes for our cobalt-based alloys Tribaloy™ T-400, Stellite™ 21 and Stellite™ 6 for producing parts by the Metal Binder Jetting Process.

With the Direct Manufacturing Research Center DMRC located at the University of Paderborn (Germany) we succeeded in doing the same with SLM for Stellite™ 6 using an innovative heating device which is the perfect match for our alloys.

The groundwork is done: we developed processes to produce specimen of astonishing quality and it was ultimately possible to print prototypes from all three alloys. So we are now capable to print pre-series and small batches in our alloys!

Producing graspable parts is one desired thing… them having the same functional properties as casted or machined parts out of our materials is what we really need. Though we know our alloys and their features like the back of our hands, these new processes influence the structure and with that the products properties greatly.

The printed prototypes were tested against our conventionally produced versions to investigate the tensile properties, wear & corrosion resistance side by side to their printability. Preliminary tests show an outstanding and promising performance compared to the conventional produced versions of these alloys. This a huge success and step forwards, which motivates us to consider 3D-printing as a real supplement of our portfolio, enabling us to close the gaps conventional processes just could not serve.

More about additive manufacturing solutions